Create bolts

To create bolts, you can either create a single bolt group or apply a component that automatically creates bolt groups.

Tekla Structures uses the same command for creating bolts, studs and holes. If you want to create only holes, do not use any bolt elements (such as bolts, washers, and nuts).

If you want to create bolts without creating holes, use the No hole option for Special hole type in the Bolt properties.

You can create different marks for bolts and holes in drawings.

Create a bolt group

Create a single bolt

-

On the

Steel tab, hold down Shift and click Bolt

to open the Bolt properties.

to open the Bolt properties.

- Under Bolt group, select Array from the Shape list.

- In the Bolt dist X and Bolt dist Y boxes, enter 0.

- Create the bolt the same way you would create a bolt group. See the instructions in the table above.

Create bolts using the Auto bolt component

Use the Auto bolt component to bolt parts and nearby parts, shim plates, splice plates, or other plates. Auto bolt follows the part rotation and finds the best rotation so that you do not need to set the work plane. With Auto bolt one bolt group can span many parts, for example, manage a splice as a single group.

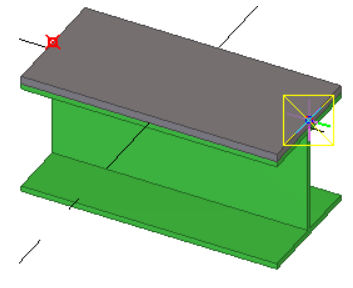

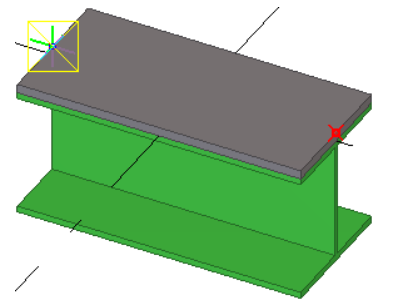

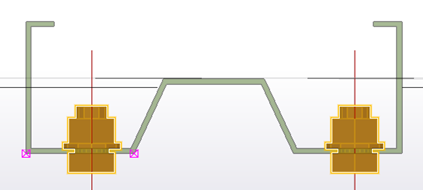

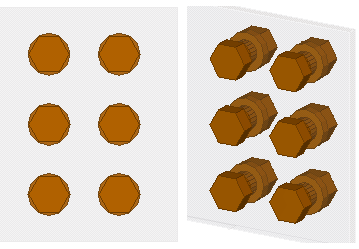

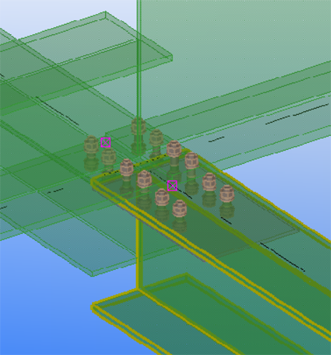

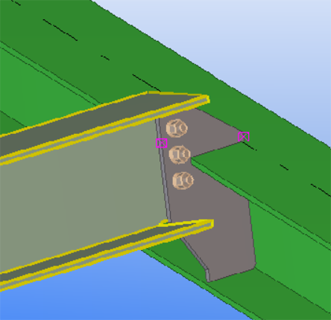

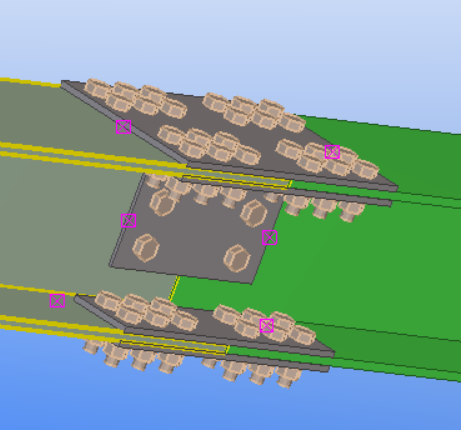

Examples

Examples of parts bolted using the Auto bolt component are shown below. The main parts and the selected points are highlighted.

Create a bolt group by exploding a component

An alternative way to create bolts is to first apply a component that includes bolt groups, and then explode the component.

Change or add bolted parts

You can change the parts a bolt group connects to.

- On the Steel tab, click Bolted parts.

- Select the bolt group.

- Reselect the main and secondary parts.

- Click the middle mouse button to finish selecting the parts.

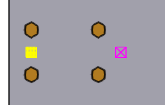

Bolt group shape

Use the Bolt group settings in the Bolt properties to select the shape of a bolt group and to determine how many bolts the bolt group contains.

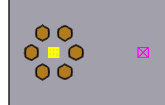

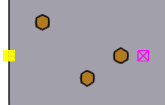

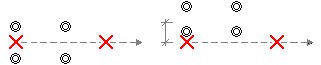

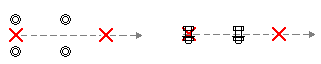

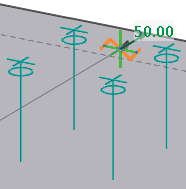

In the images below, the yellow handle indicates the origin of the bolt group, and the magenta handle indicates the x direction of the bolt group.

|

Shape |

Other bolt group settings |

Example values |

Result |

|---|---|---|---|

|

Array |

Bolt dist X Spacing between bolts, in the x direction of the bolt group. |

150 |

|

|

Bolt dist Y Spacing between bolts, in the y direction of the bolt group. |

100 |

||

|

Circle |

Number of bolts |

6 |

|

|

Diameter of the bolt group |

100 |

||

|

List |

Bolt dist X x coordinate of each bolt, from the bolt group point of origin. |

75 175 250 |

|

|

Bolt dist Y y coordinate of each bolt, from the bolt group point of origin. |

75 -50 0 |

Bolt properties

Use the Bolt properties to view or modify the properties of a bolt group. Use the Holes section to define the properties of bolt holes. The units depend on the settings in .

|

Setting |

Description |

|---|---|

|

Bolt |

|

|

Size |

Bolt diameter. |

|

Standard |

Bolt assembly standard/grade. |

|

Bolt type |

Define whether the bolts are assembled on-site or in the shop. |

|

Connect as |

Indicate whether you are bolting a secondary part or a sub-assembly. |

|

Thread in material |

Indicate if the thread of the bolt can be inside the bolted parts. Tekla Structures does not use this value when calculating the length of full-threaded bolts. |

|

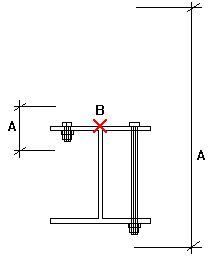

Cut length |

Indicate which parts the bolt connects. The value defines the area Tekla Structures should search for parts that belong to the bolt group. Using cut length you can determine whether the bolt will go through one flange or two. Tekla Structures searches for parts using half the cut length value, in both directions from the bolt group plane. In the illustration below, A is the cut length and B is the bolt origin. Tekla Structures calculates the search area as A/2 in both directions from point B.

Tekla Structures warns you if the cut length is too small (i.e. the bolt group contains no parts) and makes the bolt length 100 mm. If there are large gaps between the connected parts, the gap is added to the length of the bolt. Tekla Structures calculates bolt length using the total distance between the first and last surfaces. NOTE: If you want to force a bolt to be a certain length, enter a negative value for cut length (e.g. -150). NOTE: If holes or blind holes cannot be created, increase the cut length. |

|

Extra length |

Additional bolt length. Increases the material thickness that Tekla Structures uses when calculating bolt length. For example, you might need extra bolt length to allow for painting. You can also build additional lengths into bolt assemblies. |

|

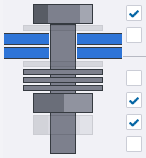

Assembly |

Select whether to create washers and nuts with the bolt. Select the Bolt checkbox to create the bolt, and then select the needed washer and nut checkboxes. For example:

If you want to create only holes without any bolts, clear all the checkboxes. |

|

Bolt group |

|

|

Shape |

Bolt group shape. You have the following options:

|

|

Bolt dist X |

Bolt spacing or coordinate, depending on the bolt group shape (Array or List). |

|

Bolt dist Y |

Bolt spacing or coordinate, depending on the bolt group shape (Array or List). |

|

Number of bolts |

Number of bolts in a circular bolt group. |

|

Diameter |

Diameter of a circular bolt group. |

|

Holes |

|

|

Tolerance |

Tolerance = Hole diameter - Bolt diameter |

| Plain hole type |

Select Through to create holes that are open throughout the part. Select Blind to create partial-depth holes that do not extend completely through parts. |

| Hole depth |

Depth of a blind hole measured from the bolt/hole reference points (yellow and magenta handles). Note that you may also need to adjust the Cut length value. |

|

Parts with special holes |

If you want to create oversized, slotted, or tapped holes, or if you want to omit holes, select the desired checkboxes to indicate which plies of the connection get special holes. |

|

Use the same settings for all special holes |

Select this checkbox to create similar special holes in each of the connected parts. The properties of the special hole that is closest to the bolt head will be used for all special holes in the bolt group. If you clear this checkbox, you can define special hole properties separately for each of the parts. |

|

Special hole type |

Oversized, slotted, tapped, or no holes. This option becomes active when you select one or more Special hole checkboxes next to Parts with special holes. |

|

Oversized |

Allowance of an oversized hole. |

|

Slotted hole X |

x allowance of a slotted hole. Zero for a round hole. To create slotted holes with an offset from the bolt center in the x direction, enter an offset value in the second box (Slot offset). |

|

Slotted hole Y |

y allowance of a slotted hole. Zero for a round hole. To create slotted holes with an offset from the bolt center in the y direction, enter an offset value in the second box (Slot offset). |

|

Core hole size |

Size of a predrilling hole. NOTE: The core hole size does not affect the DSTV output. This value is only for marking and representation of the hole in the model and drawings. |

|

The following two settings are available only in the Auto bolt component: |

|

|

Rotate slots |

If the bolt connects several parts, you may want to rotate alternate holes by 90 degrees. This allows the bolt to move in different directions. |

|

Show cut length as temporary lines |

Shows where the bolts should be placed even if they are not created.

|

|

Position |

|

|

On plane |

Move the bolt group perpendicular to the bolt group x axis.

|

|

Rotation |

Define how far the bolt group is rotated around the x axis, relative to the current work plane. For example, you can use this box to indicate on which side of the connected parts you want the bolt head to be.

|

|

At depth |

Move the bolt group perpendicular to the current work plane. |

|

Offset from |

|

|

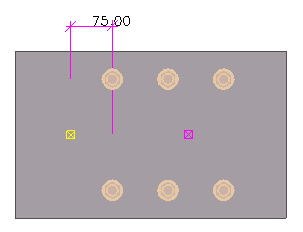

Dx, Dy, Dz |

Offsets that move the bolt group by moving the bolt group x axis. Use to change the position of the bolt group. The start point values Dx, Dy and Dz move the first end of the bolt group, relative to the bolt group x axis. The end point values move the second end of the bolt group.

An example bolt group with the Dx start point set to 75:

|

|

More |

|

|

UDAs |

Click the User-defined attributes button to open the user-defined attributes (UDAs) of the bolt. UDAs provide more information about the bolts. |

and

and  where you use a part

face, the edge of the part face that is nearest to the mouse pointer is

selected as the basis for the preview. The bolt group direction will be

perpendicular to this edge.

where you use a part

face, the edge of the part face that is nearest to the mouse pointer is

selected as the basis for the preview. The bolt group direction will be

perpendicular to this edge.

on the contextual

toolbar. Then click

on the contextual

toolbar. Then click  on the contextual

toolbar. Then select whether you want to show the center lines for profiles,

such as beams and columns, or for plates, or for both.

on the contextual

toolbar. Then select whether you want to show the center lines for profiles,

such as beams and columns, or for plates, or for both.

on the contextual

toolbar. Clicking

on the contextual

toolbar. Clicking  in the side pane to open the

in the side pane to open the

in the list at the

bottom of the dialog to not show the temporary lines.

in the list at the

bottom of the dialog to not show the temporary lines.  in the list at the

bottom of the dialog to show the temporary lines.

in the list at the

bottom of the dialog to show the temporary lines.