Stub (133)

Stub (133) is commonly used in multi-store constructions. The connection creates a plated stub that is welded to a column web and bolted to a floor beam with splice plates. The stub is shaped to fit the column as a tapered plate.

Objects created

-

Web plates

-

Flange plates

-

Weld backing bars

-

Bolts

-

Welds

Use for

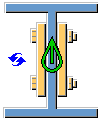

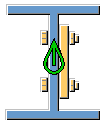

| Situation | Description |

|---|---|

|

|

Plated stub welded to a column web and bolted to a floor beam with splice plates. |

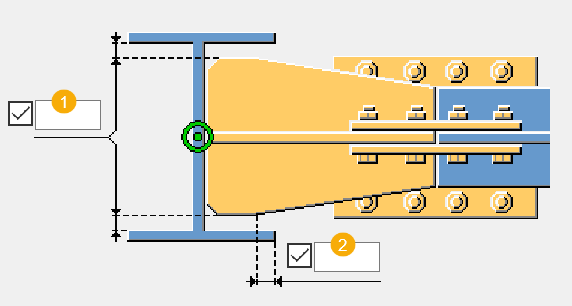

Selection order

-

Select the main part (column).

-

Select the secondary part (floor beam).

The connection is created automatically when the secondary part is selected.

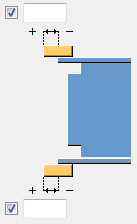

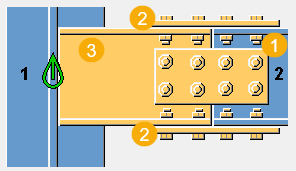

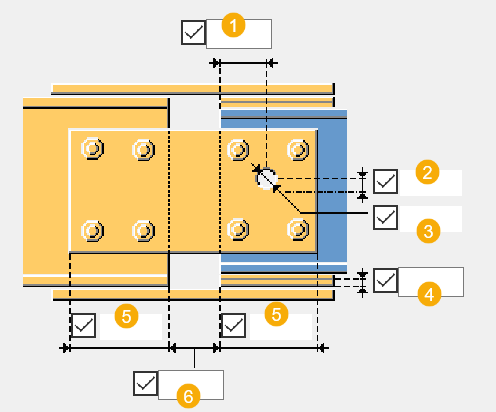

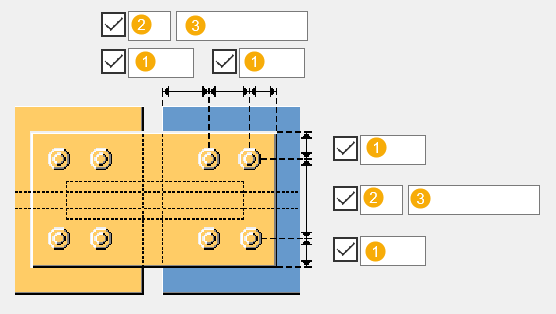

Part identification key

| Description | |

|---|---|

|

1 |

Splice |

|

2 |

Upper and lower flange plate |

|

3 |

Web plate |

Picture tab

Use the Picture tab to define the connection dimensions.

Dimensions

| Description | Default | |

|---|---|---|

|

1 |

Tolerance between the column flange and the stub top and bottom plate. |

|

|

2 |

Starting point for the chamfer |

2.0 mm |

| Description | Default | |

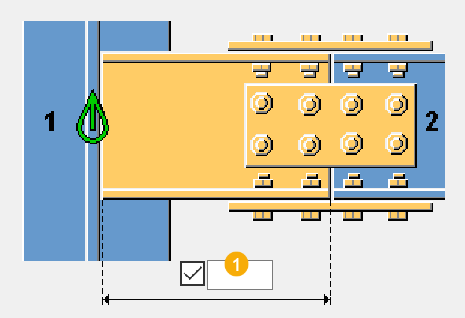

|---|---|---|

|

1 |

Stub length |

1000 mm |

Parts tab

Use the Parts tab to define the part properties.

Parts

| Option | Description |

|---|---|

|

Upper flange |

Thickness of the upper flange of the stub. |

|

Lower flange |

Thickness of the lower flange of the stub. |

|

Web |

Thickness of the web of the stub. |

|

Web plates |

Thickness, width, and height of the web plates. |

|

Flange plates |

Thickness, width, and height of the flange plates. |

|

Top int flange pl |

Thickness, width, and height of the top inner flange plates. |

|

Btm int flange pl |

Thickness, width, and height of the bottom inner flange plates. |

|

Option |

Description |

Default |

|---|---|---|

|

Pos_No |

Prefix and start number for the part position number. Some components have a second row of fields where you can enter the assembly position number. |

The default part start number is defined in the Components settings in . |

|

Material |

Material grade. |

The default material is defined in the Part material box in the Components settings in . |

|

Name |

Name that is shown in drawings and reports. |

Stub cut tab

Use the Stub cut tab to define the weld backing bars, weld access holes, beam end preparations, and flange cuts.

Parts

| Option | Description |

|---|---|

|

Backing bar |

Thickness and width of the backing bar. |

|

Option |

Description |

Default |

|---|---|---|

|

Pos_No |

Prefix and start number for the part position number. Some components have a second row of fields where you can enter the assembly position number. |

The default part start number is defined in the Components settings in . |

|

Material |

Material grade. |

The default material is defined in the Part material box in the Components settings in . |

|

Name |

Name that is shown in drawings and reports. |

|

|

Finish |

Describes how the part surface has been treated. |

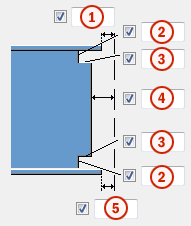

Weld access hole dimensions

|

Description |

|

|---|---|

|

1 |

Gap between the secondary part top flange and the main part. |

|

2 |

Vertical dimensions for the top and the bottom weld access holes. |

|

3 |

Horizontal dimensions for the top and the bottom weld access holes. |

|

4 |

Gap between the secondary part web and the main part. Tekla Structures adds the value you enter here to the gap you enter on the Picture tab. |

|

5 |

Gap between the secondary part bottom flange and the main part. Tekla Structures adds the value you enter here to the gap you enter on the Picture tab. |

Weld access holes

|

Option |

Description |

Default |

|---|---|---|

|

|

Default Round weld access hole AutoDefaults can change this option. |

|

|

|

Round weld access hole |

|

|

|

Square weld access hole |

|

|

|

Diagonal weld access hole |

|

|

|

Round weld access hole with a radius that you can define in

|

|

|

|

Extended cone-shaped weld access hole with a radius and dimensions that you can define in

|

|

|

|

Cone-shaped weld access hole with radiuses that you can define in

Capital R defines the large radius (height). Small r defines the small radius. |

R = 35 r = 10 |

Beam end preparation

|

Option |

Description |

|---|---|

|

|

Default Top and bottom flange are prepared. AutoDefaults can change this option. |

|

|

Automatic Top and bottom flange are prepared. |

|

|

Beam end is not prepared. |

|

|

Top and bottom flange are prepared. |

Flange cut

|

Option for top flange |

Option for bottom flange |

Description |

|---|---|---|

|

|

|

Default Flange is not cut. AutoDefaults can change this option. |

|

|

|

Flange is not cut. |

|

|

|

Flange is cut. |

Weld backing bars

| Option | Option | Description |

|---|---|---|

|

|

|

Default No backing bars are created. AutoDefaults can change this option. |

|

|

|

No backing bars are created. |

|

|

|

Backing bars are created inside the flanges. |

|

|

|

Backing bars are created outside the flanges. |

Weld backing bar length

Enter the length of the weld backing bar in the box below the options.

|

Option |

Description |

|---|---|

|

|

Default Absolute length of the backing bar AutoDefaults can change this option. |

|

|

Absolute length of the backing bar |

|

|

Extension beyond the edge of the flange |

Weld backing bar position

|

Option |

Description |

|---|---|

|

|

Enter a positive or a negative value to move the front end of the backing bar relative to the end of the flange. |

Splice tab

Use the Splice tab to define clearances between the parts and connection parts, and values for the properties shared with two or more connection parts.

Splice

| Option | Description |

|---|---|

|

Default |

Stub (133) is used to create the splice. Define the properties of web plates, flange plates, and top and bottom internal plates on the Parts tab, splice properties on the Splice tab, and bolt properties on the Web Bolts and Flange Blt tabs. |

|

Splice connection (77) |

The Splice connection (77) component is used to create the splice. Select which settings are used for the component in the Splice connection (77) list. If you select Specified, enter the name of the attribute file to use in the Parameter box. |

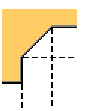

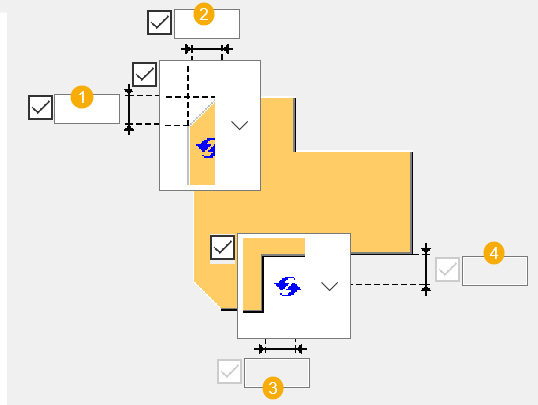

Chamfer dimensions

| Description | |

|---|---|

|

1 |

Vertical chamfer dimension. |

|

2 |

Horizontal chamfer dimension. |

|

3 |

Horizontal corner dimension for tee shaped stub plate. |

|

4 |

Vertical corner dimension for tee shaped stub plate. |

Chamfer type

|

Option |

Description |

|---|---|

|

|

Default Line chamfer AutoDefaults can change this option. |

|

|

No chamfer |

|

|

Line chamfer |

|

|

Convex arc chamfer |

|

|

Concave arc chamfer |

Corner shape

| Option | Description |

|---|---|

|

|

Default Square AutoDefaults can change this option. |

|

|

Square |

|

|

Line |

|

|

Concave |

Web plates

| Option | Description |

|---|---|

|

|

Default Two web plates are created. |

|

|

Two web plates are created. |

|

|

Web plate is created |

|

|

Web plate is created |

Stub flange plate shape

| Option | Description |

|---|---|

|

|

Default Tapered AutoDefaults can change this option. |

|

|

Tapered |

|

|

Tee shaped |

Dimensions

| Description | Default | |

|---|---|---|

|

1 |

Distance between lifting hole and part edge. |

0.0 mm |

|

2 |

Lifting hole vertical offset from the plate center line. |

30 mm |

|

3 |

Hole diameter. |

|

|

4 |

Thickness of shim plates. When the height of the plates created by the component and the secondary part height are different, shim plates are created. |

10 mm |

|

5 |

Width of the connection area between the web plate and the beam or stub. |

|

|

6 |

Clearance between parts. |

0.0 mm |

Lifting hole

| Option | Description |

|---|---|

|

|

Default Lifting hole is not created. AutoDefaults can change this option. |

|

|

Lifting hole is not created. |

|

|

Lifting hole is created. |

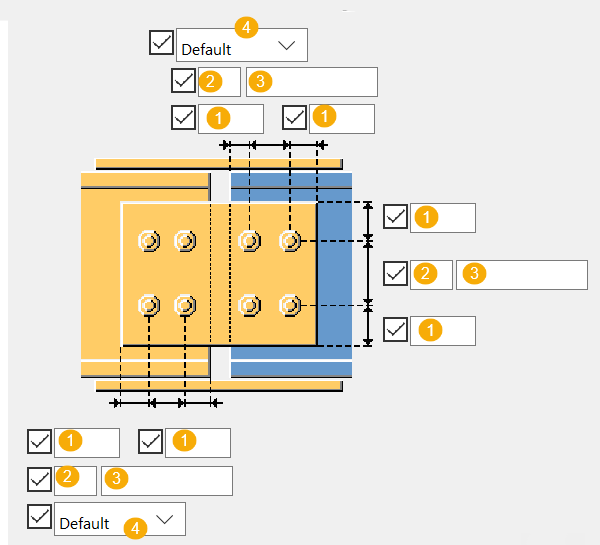

Web bolts tab

Use the Web bolts tab to define the bolt group dimensions and bolts properties.

Bolt group dimensions

| Description | |

|---|---|

|

1 |

Bolt edge distance. Edge distance is the distance from the center of a bolt to the edge of the part. |

|

2 |

Number of bolts. |

|

3 |

Bolt spacing. Use a space to separate bolt spacing values. Enter a value for each space between bolts. For example, if there are 3 bolts, enter 2 values. |

|

4 |

Location where the bolts should be attached. |

Bolt basic properties

|

Option |

Description |

Default |

|---|---|---|

|

Bolt size |

Bolt diameter. |

Available sizes are defined in the bolt assembly catalog. |

|

Bolt standard |

Bolt standard to be used inside the component. |

Available standards are defined in the bolt assembly catalog. |

|

Tolerance |

Gap between the bolt and the hole. |

|

|

Thread in mat |

Defines whether the thread may be within the bolted parts when bolts are used with a shaft. This has no effect when full-threaded bolts are used. |

Yes |

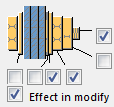

Slotted holes

You can define slotted, oversized, or tapped holes.

|

Option |

Description |

Default |

|---|---|---|

|

1 |

Vertical dimension of slotted hole. |

0, which results in a round hole. |

|

2 |

Horizontal dimension of slotted hole, or allowance for oversized holes. |

0, which results in a round hole. |

|

Hole type |

Slotted creates slotted holes. Oversized creates oversized holes. No hole does not create holes. Tapped creates tapped holes. |

|

|

Rotate Slots |

When the hole type is Slotted, this option rotates the slotted holes. |

|

|

Slots in |

Part(s) in which slotted holes are created. The options depend on the component in question. |

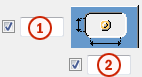

Bolt assembly

The selected check boxes define which component objects (bolt, washers, and nuts) are used in the bolt assembly.

If you want to create a hole only, clear all the check boxes.

To modify the bolt assembly in an existing component, select the Effect in modify check box and click Modify.

Bolt length increase

Define how much the bolt length is increased. Use this option when, for example, painting requires the bolt length to be increased.

Staggering of bolts

|

Option |

Description |

|---|---|

|

|

Default Not staggered AutoDefaults can change this option. |

|

|

Not staggered |

|

|

Staggered type 1 |

|

|

Staggered type 2 |

|

|

Staggered type 3 |

|

|

Staggered type 4 |

Flange Blt tab

Use the Flange Blt tab to define the bolt group dimensions and bolt properties.

Bolt group dimensions

| Description | |

|---|---|

|

1 |

Bolt edge distance. Edge distance is the distance from the center of a bolt to the edge of the part. |

|

2 |

Number of bolts. |

|

3 |

Bolt spacing. Use a space to separate bolt spacing values. Enter a value for each space between bolts. For example, if there are 3 bolts, enter 2 values. |

Bolt basic properties

|

Option |

Description |

Default |

|---|---|---|

|

Bolt size |

Bolt diameter. |

Available sizes are defined in the bolt assembly catalog. |

|

Bolt standard |

Bolt standard to be used inside the component. |

Available standards are defined in the bolt assembly catalog. |

|

Tolerance |

Gap between the bolt and the hole. |

|

|

Thread in mat |

Defines whether the thread may be within the bolted parts when bolts are used with a shaft. This has no effect when full-threaded bolts are used. |

Yes |

Staggering of bolts

|

Option |

Description |

|---|---|

|

|

Default Not staggered AutoDefaults can change this option. |

|

|

Not staggered |

|

|

Staggered type 1 |

|

|

Staggered type 2 |

|

|

Staggered type 3 |

|

|

Staggered type 4 |

General tab

Click the link below to find out more:

Design tab

Click the link below to find out more:

Analysis tab

Click the link below to find out more:

Welds

Click the link below to find out more: