Web stiffened base plate (1016)

Web stiffened base plate (1016) creates a base plate with vertical, horizontal, and sloping web stiffeners.

Objects created

-

Base plate

-

Stiffeners

-

Shim plates (optional)

-

Leveling plate (optional)

-

Shear key (optional)

-

Extra plates connecting the anchor rods

-

Anchor rods

-

Bolts

-

Welds

-

Additional component (optional)

Use for

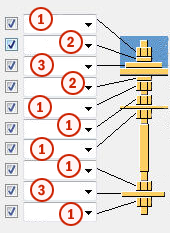

|

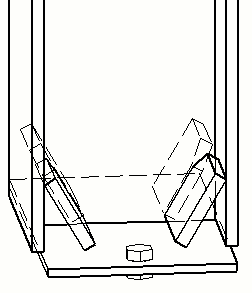

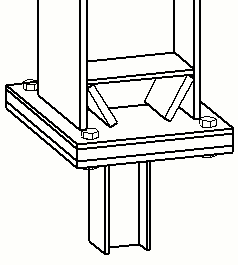

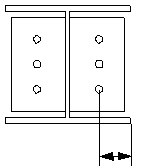

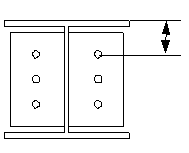

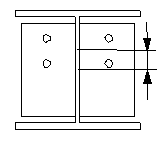

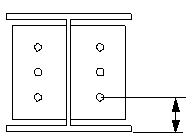

Situation |

Description |

|---|---|

|

|

Web stiffened base plate |

|

|

Web stiffened base plate with a leveling plate, a shim plate, horizontal stiffener and a shear key |

Before you start

Create a column or a beam.

Selection order

-

Select the main part (column or beam).

-

Pick a position.

The detail is created automatically.

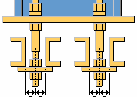

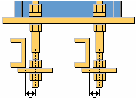

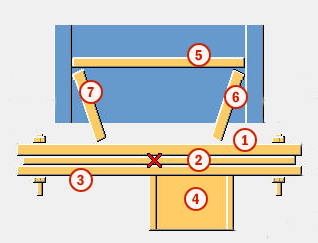

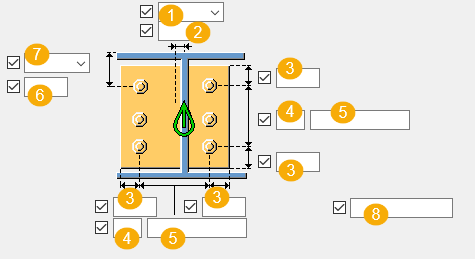

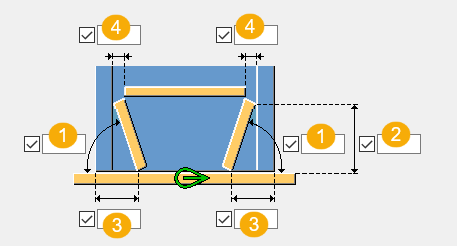

Part identification key

|

Part |

|

|---|---|

|

1 |

Base plate |

|

2 |

Shim plate |

|

3 |

Leveling plate |

|

4 |

Shear key |

|

5 |

Upper horizontal stiffener |

|

6 |

Upper flange stiffener |

|

7 |

Lower flange stiffener |

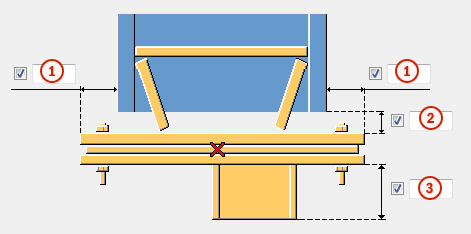

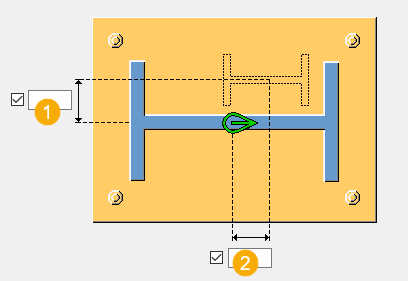

Picture tab

Use the Picture tab to control the position of the base plate and the shear key offset.

Dimensions

|

Description |

|

|---|---|

|

1 |

Distance from the flange to the edge of the base plate. |

|

2 |

Weld gap. |

|

3 |

Height of the shear key. |

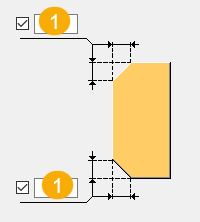

Shear key offset

| Description | |

|---|---|

|

1 |

Shear key vertical offset from the main part center. |

|

2 |

Shear key horizontal offset from the main part center. |

Parts tab

Use the Parts tab to control the dimensions of the base plate, upper and lower flange stiffener, shear key, leveling plate, upper horizontal stiffener, and shim plates.

Plate

|

Description |

Default |

|

|---|---|---|

|

Plate |

Base plate thickness. The dimensions on the Picture and Bolts tab determine the base plate width and length. |

|

|

Upper fl. stiffener |

Upper flange stiffener thickness, width and height. |

Thickness = thickness of the main part flange Height = determined by the size of the main part Width = inner side flange distance |

|

Lower fl. stiffener |

Lower flange stiffener thickness, width and height. |

Thickness = thickness of the main part flange Height = determined by the size of the main part Width = inner side flange distance |

|

Additional beam |

Select the shear key profile from the profile catalog. |

|

|

Additional beam rotation |

Select the shear key rotation type and define the rotation angle. | |

|

Additional beam welded to |

Define to which plate the shear key is welded. |

|

|

Leveling plate |

Leveling plate thickness, width and height. |

|

|

Leveling plate hole diameter |

Leveling plate hole diameter. |

|

|

Upper horizontal stiff |

Upper horizontal stiffener thickness, width and height. |

Thickness = 0 mm |

|

Fitting plate |

Shim plate thickness, width and height. Define up to three different shim plates. |

|

|

Number of fitting pl. |

Number of shim plates for each thickness. |

1 |

|

Option |

Description |

Default |

|---|---|---|

|

Pos_No |

Prefix and start number for the part position number. Some components have a second row of fields where you can enter the assembly position number. |

The default part start number is defined in the Components settings in . |

|

Material |

Material grade. |

The default material is defined in the Part material box in the Components settings in . |

|

Name |

Name that is shown in drawings and reports. |

|

|

Class |

Part class number. |

|

|

Finish |

Describes how the part surface has been treated. |

Parameters tab

Use the Parameters tab to control the component used inside Web stiffened base plate (1016).

Using additional components

You can use additional system or custom components to modify the column end or the base plate. For example, you can create special backing plates, weld preparations, and weld access holes for the column end.

If you use additional system or custom components, you need to manage the column end or the base plate properties in the additional component in question. When using several components, there may be multiple welds and cuts.

| Part |

Description |

|---|---|

|

Component |

Select a system or a custom component from the Applications & components catalog. |

|

Attributes |

Select an attribute file for the component. |

|

Input |

Define to which parts the selected component is applied.

|

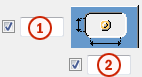

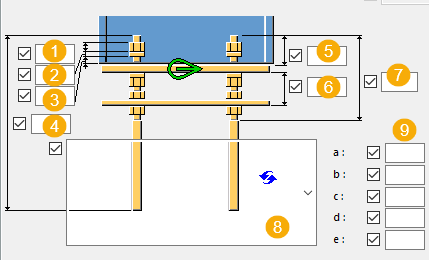

Bolts tab

Use the Bolts tab to control the bolt properties.

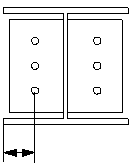

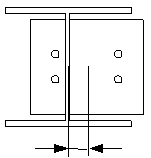

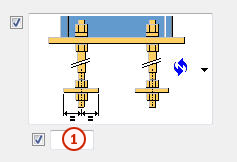

Bolt group dimensions

|

Description |

|

|---|---|

|

1 |

Select how to measure the dimensions for horizontal bolt group position.

|

|

2 |

Dimension for horizontal bolt group position. |

|

3 |

Bolt edge distance. Edge distance is the distance from the center of a bolt to the edge of the part. |

|

4 |

Number of bolts. |

|

5 |

Bolt spacing. Use a space to separate bolt spacing values. Enter a value for each space between bolts. For example, if there are 3 bolts, enter 2 values. |

|

6 |

Dimension for vertical bolt group position. |

|

7 |

Select how to measure the dimensions for vertical bolt group position.

|

|

8 |

Define which bolts are deleted from the bolt group. Enter the bolt numbers of the bolts to be deleted and separate the numbers with a space. Bolt numbers run from left to right and from top to bottom. |

Bolt basic properties

|

Option |

Description |

Default |

|---|---|---|

|

Bolt size |

Bolt diameter. |

Available sizes are defined in the bolt assembly catalog. |

|

Bolt standard |

Bolt standard to be used inside the component. |

Available standards are defined in the bolt assembly catalog. |

|

Tolerance |

Gap between the bolt and the hole. |

|

|

Thread in mat |

Defines whether the thread may be within the bolted parts when bolts are used with a shaft. This has no effect when full-threaded bolts are used. |

Yes |

|

Site/Workshop |

Location where the bolts should be attached. |

Site |

Cut length

Defines the depth at which Tekla Structures searches for the sections of the bolted parts. You can determine whether the bolt will go through one flange or two.

Comment

You can define a comment.

Slotted holes

You can define slotted, oversized, or tapped holes.

|

Option |

Description |

Default |

|---|---|---|

|

1 |

Vertical dimension of slotted hole. |

0, which results in a round hole. |

|

2 |

Horizontal dimension of slotted hole, or allowance for oversized holes. |

0, which results in a round hole. |

|

Hole type |

Slotted creates slotted holes. Oversized creates oversized holes. No hole does not create holes. Tapped creates tapped holes. |

|

|

Rotate Slots |

When the hole type is Slotted, this option rotates the slotted holes. |

|

|

Slots in |

Part(s) in which slotted holes are created. The options depend on the component in question. |

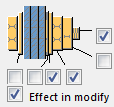

Bolt assembly

The selected check boxes define which component objects (bolt, washers, and nuts) are used in the bolt assembly.

If you want to create a hole only, clear all the check boxes.

To modify the bolt assembly in an existing component, select the Effect in modify check box and click Modify.

Bolt length increase

Define how much the bolt length is increased. Use this option when, for example, painting requires the bolt length to be increased.

Staggering of bolts

|

Option |

Description |

|---|---|

|

|

Default Not staggered AutoDefaults can change this option. |

|

|

Not staggered |

|

|

Staggered type 1 |

|

|

Staggered type 2 |

|

|

Staggered type 3 |

|

|

Staggered type 4 |

Stiffeners tab

Use the Stiffeners tab to control the stiffener angle, position and selection.

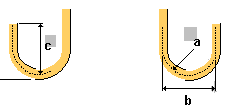

Stiffener angle and position

|

Description |

Default |

|

|---|---|---|

|

1 |

Stiffener angle. |

60 degrees |

|

2 |

Height of the stiffener. |

|

|

3 |

Distance of the stiffener from the column edge. |

|

|

4 |

Gap between the upper horizontal stiffener and the main part flange. |

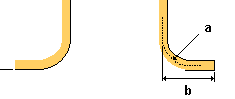

Stiffener chamfer dimensions

|

Description |

|

|---|---|

|

1 |

Size of the chamfer. |

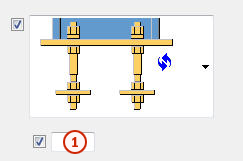

Stiffener orientation

|

Option |

Description |

|---|---|

|

|

Default Stiffeners are sloped. AutoDefaults can change this option. |

|

|

Stiffeners are sloped. |

|

|

Stiffeners are vertical. |

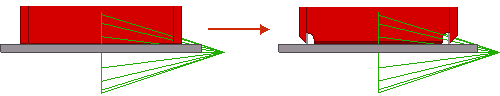

Flange cuts

|

Option |

Description |

|---|---|

|

|

Default Flanges are not cut. Stiffeners are sloped. AutoDefaults can change this option. |

|

|

Flanges are not cut. Stiffeners are sloped. |

|

|

Flanges are cut. Stiffeners are sloped. If you have selected to create vertical stiffeners, flanges cannot be cut. |

Anchor rods tab

Use the Anchor rods tab to control the creation of different types of anchor rods.

Anchor rod dimensions

|

Option |

Description |

|---|---|

|

Rod profile |

Anchor rod profile. |

|

Nut profile |

Nut profile. |

|

Washer profile |

Washer profile. |

|

Plate washer |

Plate washer thickness, width and height. |

|

Cast plate |

Cast plate thickness, width and height. |

|

Grout |

Grout thickness. Grouting helps you to model columns to the top of concrete parts and place the base plate correctly. It also makes it easier to dimension the detail in GA drawings. The cast unit type of the grout is Cast in place. By default, no grouting is created. Select whether the grouting is created with or without slopes above or below the detail creation point. This also affects the shim plates. |

Anchor rod part properties

| Option | Description | Default |

|---|---|---|

|

Pos_no |

Prefix and start number for the part position number. Some components have a second row of fields where you can enter the assembly position number. |

The default part start number is defined in the Components settings in . |

|

Material |

Material grade. |

The default material is defined in the Part material box in the Components settings in . |

|

Name |

Name that is shown in drawings and reports. |

|

|

Class |

Part class number. |

|

|

Finish |

Describes how the part surface has been treated. |

|

|

Comment |

Add a comment about the part. |

Base plate with

Select whether to create the base plate with bolts, anchor rods, or a custom component.

By default, the base plate is created with Bolts.

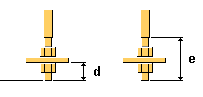

Anchor rod dimensions

| Description | Default | |

|---|---|---|

|

1 |

Size or the length of the nut. |

anchor rod diameter |

|

2 |

Size or the thickness of the washer. |

half of nut size |

|

3 |

Gap between the base plate and nut or washer created above the base plate. |

|

|

4 |

Length of the anchor rod. |

500 mm |

|

5 |

Length of the anchor rod above the base plate. |

50 mm |

|

6 |

Distance between the cast plate and the base plate. |

60 mm |

|

7 |

Length of the upper thread. |

0 mm |

|

8 |

Anchor rod types. |

|

|

9 |

Anchor rod dimensions. |

Anchor rod types

|

Option |

Description |

|

|---|---|---|

|

|

Default Type 1 AutoDefaults can change this option. |

|

|

|

Type 1 |

|

|

|

a Radius of the hook b Width of the hook |

a = 2*anchor bar diameter b = 1/5 of anchor bar length |

|

|

a Radius of the hook b Width of the hook c Height of the hook |

c = same as width of the hook |

|

|

d Length of the anchor rod below the extra plate e Length of the lower thread |

d = 2*nut size e = 4*nut size plus thickness of extra plate |

Hook direction

|

Option |

Description |

|---|---|

|

|

Default Type 1 AutoDefaults can change this option. |

|

|

Type 1 |

|

|

Type 2 |

|

|

Type 3 |

|

|

Type 4 |

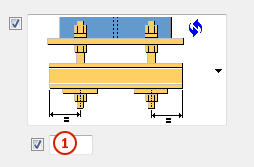

Bolting direction

You can define the bolting direction if you have created the base plate with bolts.

|

Option |

Description |

|---|---|

|

|

Default Bolting direction 1 AutoDefaults can change this option. |

|

|

Bolting direction 1 |

|

|

Bolting direction 2 |

Cast plate holes tolerance

|

Option |

Description |

Default |

|---|---|---|

|

Cast plate holes tolerance |

Tolerance of the cast plate holes. |

same as bolt tolerance |

Washer hole tolerance

|

Option |

Description |

|---|---|

|

Create hole in washer |

By default, a hole is not created in the washer. Tolerance of the washer hole. |

Create assembly from all anchors

Define whether anchors are included in an anchor rod assembly. You can also include leveling plates into the assembly.

Create

|

Description |

|

|---|---|

|

1 |

Create the nut profile. |

|

2 |

Create the washer profile. |

|

3 |

Create the washer plate. |

Anchor rod assembly

Define which parts of the anchor rod are included in the anchor rod assembly.

You can weld the washer plates above and below the base plate.

Extra plates tab

Use the Extra plates tab to control the placement, rotation, and type of the profiles (extra profile 1) created at the bottom of each anchor bar and the profiles (extra profile 2) that connect rows of anchor bars.

Part dimensions

|

Option |

Description |

Default |

|---|---|---|

|

Extra profile 1 |

First extra profile by selecting it from the profile catalog. |

PL10*100 |

|

Extra profile 2 |

Second extra profile by selecting it from the profile catalog. |

Part properties

|

Option |

Description |

Default |

|---|---|---|

|

Pos_No |

Prefix and start number for the part position number. Some components have a second row of fields where you can enter the assembly position number. |

The default part start number is defined in the Components settings in . |

|

Material |

Material grade. |

The default material is defined in the Part material box in the Components settings in . |

|

Name |

Name that is shown in drawings and reports. |

|

|

Class |

Part class number. |

|

|

Finish |

Describes how the part surface has been treated. |

Edge distance of extra profile 1

|

Description |

Default |

|

|---|---|---|

|

1 |

Edge distance of extra profile 1. |

50 mm |

Type and direction of extra profile 1

|

Option |

Description |

|---|---|

|

|

Default Type 1 AutoDefaults can change this option. |

|

|

Type 1 |

|

|

Type 2 |

|

|

Type 3 |

Edge distance of extra profile 2

|

Description |

Default |

|

|---|---|---|

|

1 |

Distance of extra profile 2 from the axis of the anchor bar. |

Half of the nut size or anchor bar diameter |

Extra profile 2 type

|

Option |

Description |

|---|---|

|

|

Default Type 1 AutoDefaults can change this option. |

|

|

Type 1 |

|

|

Type 2 |

|

|

Type 3 |

|

|

Type 4 |

|

|

Type 5 |

|

|

Type 6 |

Length of extra profile 2

|

Description |

Default |

|

|---|---|---|

|

1 |

Length of extra profile 2 from the axis of the anchor bar. |

50 mm |

Direction of extra profile2

|

Option |

Description |

|---|---|

|

|

Default Type 1 AutoDefaults can change this option. |

|

|

Type 1 |

|

|

Type 2 |

Extra profile 1 properties

|

Option |

Description |

Default |

|---|---|---|

|

Hole tolerance |

Hole tolerance of extra profile 1. |

Same as bolt tolerance |

|

Profile rotation |

Profile rotation of extra profile 1. |

Front |

Extra profile 2 rotation

|

Option |

Description |

Default |

|---|---|---|

|

Extra profile 2 rotation |

Profile rotation of extra profile 2. |

Front |

General tab

Click the link below to find out more:

Analysis tab

Click the link below to find out more:

Welds

Click the link below to find out more: